- Shriram IE., Wadala Mumbai - 31

- response@urjatransformers.com

Our Products

- Home

- Products

- Distribution Transformers

Distribution Transformers Manufacturer, Supplier

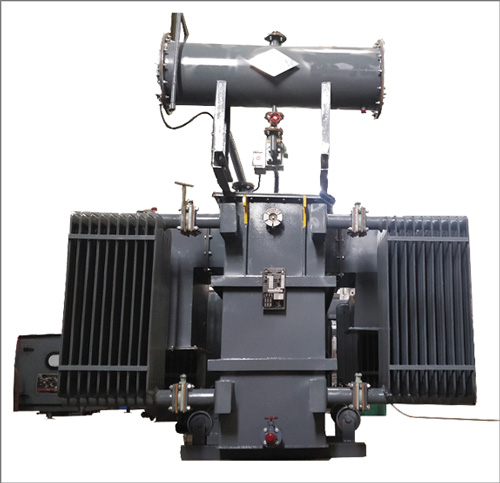

Established as a market leader in the transformer industry, Urja Techniques (India) Pvt Ltd specializes in manufacturing impeccable Distribution transformers tailored to a broad spectrum of applications. Our product range includes solar converter duty transformers, earthing transformers, furnace transformers, reactor transformers, and dry type transformers. Urja Techniques is committed to delivering best quality and performance, leveraging our exceptional testing facilities that adhere to the highest international standards, including IS, IEC and ANSI. The transformers manufactured are in compliance with Bureau of Indian Standards IS 2026, IS 1180 (Part 1): 2014 Level 2, and the Bureau of Energy Efficiency (BEE) 4 Star rating, reflecting our unwavering commitment to delivering quality products.

Introduction:

A distribution transformer is an electrical transformer used in power distribution systems to convert high voltage electricity into lower voltages suitable for use by residential, commercial, and industrial consumers. The primary objective of a distribution transformer is to bring down the voltage from the transmission or distribution lines to the level that can be safely used by the end users. Urja Techniques offers a comprehensive range of high quality, energy efficient distribution transformers designed to optimize performance, minimize losses and provide exceptional reliability. These transformers are typically found on utility poles or in ground level substations, connecting the high voltage distribution grid to local low voltage networks. Distribution transformers are essential components of electrical power systems and come in various sizes and configurations, depending on the voltage levels, power rating and the specific requirements of the distribution network they serve.

Features:

1.Voltage transformation: The primary function is to convert high voltage electricity (usually in the range of 11 kV to 33 kV) to lower voltages (e.g., 120V, 240V, or 415V) suitable for residential, commercial and industrial use.

2.Load management: Distribution transformers are designed to handle varying loads throughout the day, as electricity consumption fluctuates depending on the time and day of the week.

3.Efficiency: Modern distribution transformers are designed to minimize energy losses, improving the overall efficiency of the power distribution system.

4.Insulation and cooling: Distribution transformers utilize various types of insulation and cooling methods (such as oil-filled or dry-type transformers) to ensure safe and reliable operation.

5.Overload protection: They often include protective devices to prevent damage due to overloading or other electrical faults.

Advantages:

Distribution transformers from Urja Techniques offer numerous benefits, including improved energy efficiency, reduced operational costs, and enhanced reliability. By employing cutting-edge design and manufacturing techniques, our transformers minimize energy losses, ensuring optimal performance and reduced carbon emissions. The low noise output and compact design of our transformers allow for versatile installation options in various environments. Moreover, the ease of maintenance and robust safety features ensure a hassle-free experience and long-term dependability for our customers.

Technical Specifications & Industry Nomenclature

Our distribution transformerrange is the cornerstone of efficient power delivery, often referred to in the utility sector as a service transformer or a primary step-down transformer. These units are precision-engineered to reduce high-voltage transmission levels to usable consumer voltages, typically ranging from 11kV or 33kV down to 433V/240V. Depending on the installation environment, we provide various configurations including the rugged pole-mounted transformer for overhead lines and the tamper-proof pad-mounted transformer for underground urban distributions.

To optimize energy efficiency and minimize "no-load" losses, our designs utilize high-grade CRGO (Cold Rolled Grain Oriented) silicon steel cores. Customers can choose between copper wound units for maximum conductivity and compact size, or aluminum wound distribution transformers for a lightweight, cost-effective solution. Whether you require a liquid-immersed (oil-cooled) unit with ONAN cooling for outdoor durability or a dry-type distribution transformer for indoor safety, our equipment meets stringent global standards for reliability. From single-phase residential units to high-capacity three-phase industrial models, these transformers are built to provide a stable, long-term power interface.

Distribution Transformer

Market Demand & Export Reach: As a primary supplier of distribution transformers, we cater to rapid urbanization projects in Noida, Lucknow, and Hyderabad, as well as rural electrification drives across Bihar and Madhya Pradesh. Our units are a top choice for DISCOMS in Maharashtra and Uttar Pradesh. Globally, our distribution range is widely exported to African nations (such as Kenya and Nigeria) and Southeast Asian markets like the Philippines, supporting their growing residential and utility networks.

Why Choose Urja Techniques:

Our primary objective has always been to achieve customer satisfaction by continuously enhancing our focus on quality, productivity and cost efficiency. Our esteemed clients rely on us for our adherence to international quality standards, tailored solutions and timely service delivery, which adds significant value for customers. In order to meet the increasing demands of the industry, we are supported by a capable workforce that forms the backbone of our business. Our team consists of seasoned technicians and skilled workers who cater to a diverse range of clients. They possess extensive expertise in their respective fields, enabling us to successfully fulfill requirements of our clients.

Distribution transformers are classified into different categories based on certain factors such as :

● Mounting location - pole, pad, underground vault

● Type of insulation - liquid-immersed or dry-type

● Number of Phases - single-phase or three-phase

● Voltage class

● Basic impulse insulation level (BIL).